The Replenishment calculation performs a lot of steps to provide the suggested quantities in the Purchase Replenishment Journal, Transfer Replenishment Journal, and Redistribution Replenishment Journal.

The system supports a logging functionality showing the used Replenishment Data, Inventory, Sales information, and which decision and formulas were used to calculate the suggested quantity. This can be useful for the user to understand the result of the calculation process.

The Calculation Log Lines action is available on the Replenishment Journal pages: click Navigate - Line - Calculation Log Lines.

You can select the Create Calc. Log Lines check box in the Replen. Setup page to activate the logging.

The logging functionality should only be used occasionally to investigate data and decisions in the replenishment quantity.

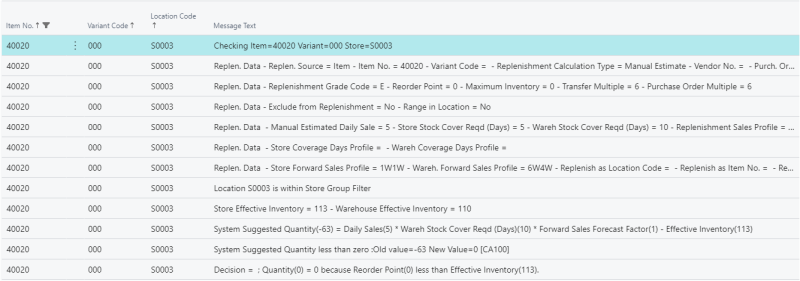

Example of Log Lines

The above image shows the Replenishment Log for the item 40030 and store S0003.

Example:

| Checking Item=40030 Variant= Store=S0003 |

| Explanation: Identifies the Item No., Variant Code and Store. |

| Replen. Data - Replen. Source = Item - Item No. = 40030 - Variant Code = - Replenishment Calculation Type = Manual Estimate - Vendor No. = - Purch. Order Delivery = To Warehouse |

| Replen. Data - Replenishment Grade Code = E - Reorder Point = 4 - Maximum Inventory = 100 - Transfer Multiple = 1 - Purchase Order Multiple = 1 |

| Replen. Data - Exclude from Replenishment = No - Range in Location = No |

| Replen. Data - Manual Estimated Daily Sale = 8 - Store Stock Cover Reqd (Days) = 4 - Wareh Stock Cover Reqd (Days) = 25 - Replenishment Sales Profile = |

| Replen. Data - Store Coverage Days Profile = - Wareh Coverage Days Profile = |

| Replen. Data - Store Forward Sales Profile = - Wareh. Forward Sales Profile = - Replenish as Location Code = - Replenish as Item No. = - Replenish as Item No - Method = Total |

| Explanation: The lines starting with the text Replen. Data are the result of the Replenishment Data search. The text Replen. Source = informs about the Replenishment Data source (Item Store, Item or Data Profile record. This example is from the item record. If the Replen. Source were of type Data Profile, the next line will be to inform which Data Profile record is being used. |

| Location S0003 is within Store Group Filter |

| Explanation: Checks if the Location is within the Store Group Filter. |

| Store Effective Inventory = 8 - Warehouse Effective Inventory = 80 |

| Explanation: Effective Inventory status of the Store and the Warehouse. |

| System Suggested Quantity(192) = Daily Sales(8) * Wareh Stock Cover Reqd (Days)(25) * Forward Sales Forecast Factor(1) - Effective Inventory(8) |

| Explanation: The calculation formula and values to calculate the System Suggested Quantity. This is the quantity you need in the store to be able to sell for the next 25 days, given a forecast of 200 and having 8 pieces in stock. |

| Decision = Based on Calculated Need; Quantity(192) = SSQ (192) because Reorder Point(4) less Demand (200). |

| Decision = Brought to Maximum Inventory - Quantity(92) = Maximum Inventory(100) - Effective Inventory(8). |

| Explanation: The system brings the System Suggested Quantity to the Maximum Inventory value minus the Effective Inventory. |

| Adjust Item quantity from 192 to 112. Warehouse Effective Inventory(80) is less than Quantity(192) then Quantity(192) - Warehouse Effective Inventory(80) = Quantity(112) [AD202] |

|

Explanation: The Purchase Replenishment Journal is to re-stock the warehouse. The System Suggested Quantity is 192 and the Effective Inventory for the warehouse is 80 and therefore the system will replenish the difference of the two numbers or 112. |

| Adjust Record quantity from 92 to 54 - Quantity to Cross Dock adjusted from 0 to 0 |

| Explanation: The system then adjusts the record for item 40030 and store S0003. The record has 92 of 192 (92/192) = 0,48 and therefore it will be 112 * 0,48 = 54. The quantity in the record has then been adjusted according to proportionally from the older quantity. |